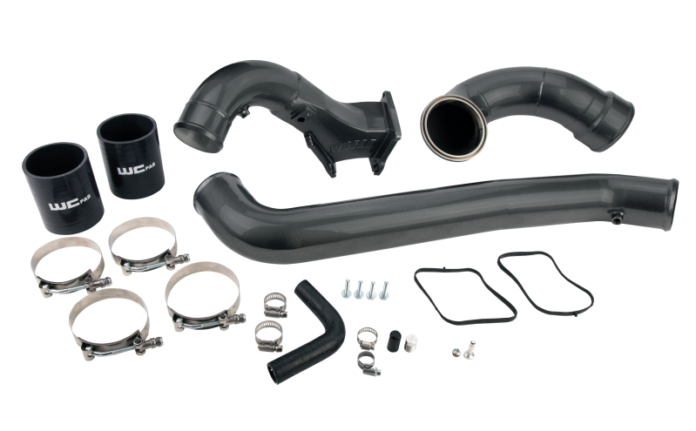

It’s no mystery that this Cummins is the ability plant of alternative within the diesel efficiency realm. However, anytime critical power make on this section, you’ll be able to guess the Chevy people are in upon this, too. Following its beginning in 2001, this duramax parts provided in its heavy-duty vans have loved loyal followers — together with an enormous growth in aftermarket assist due to numerous homeowners who had been keen to accelerate the envelope. While fanatics started to search out the weak hyperlinks on this state-of-the-art, this aftermarket delivered them larger, higher, more vital elements to carry as much as four-digit energy injuries, two thousand lb-ft like torque, plus 100 psi of increase.

Observe alongside as they spotlight the unique exhausting components and machining methods that went right into a bulletproof construct. Almost every little thing from the bottom up; however, the block has improved on that LML system Duramax. Among the final bolt torqued on that lengthy block, massive gas and air had attached to the comparison, and that was just lately shot up for the primary time and launched again into the desert.

Twisted Metallic

The exterior of diesel retailers and some choose race groups. Since you may get away with performing a little bit of torque and horsepower on the inventory legally, most diesel fanatics don’t permit the “constructed motor” route till they compel.

Nicely, after clearing greater than 800 and almost 1,600 lb-ft about torque on this chassis dyno, every eight manufacturing unit connecting rods on this early to make LML Duramax on this article regarded like that.

Cast-Aluminum Pistons

Intending to survive excessive in-cylinder warmth and restrict growth, a collection of 0.020 inches up, 4.075-inch forged-aluminum devices acquired the nod. Radiused, 0.075 inches valve holes were added since high-rpm protection and cut back fatigue and stress.

Those pistons comprise performance-oriented gas bowls that design to cut back erosion points attributable to extreme strain, lengthy gas injector period, and excellent injection timing.

Crankshaft Preservation

Crankshaft snapped are a severe drawback on constructed Duramax diesel that view avenue use. The mix of excessive rpm plus a large harmonious balancer can genuinely reveal that crankshaft. By placing in a sturdy keyway within the crankshaft and including an alternate firing position camshaft, Duramax diesel builders understand that making the crankshaft since near internally set as attainable is one of the best ways to enhance the durability of that vitally vital part.

Added Insurance coverage

One weak hyperlink within the manufacturing unit Duramax crankshaft survives within the snout’s 5 mm dowel bars. With massive energy within the combine, the damper understands to shear that dowel pins. While this occurs, the harmonious balancer will turn on this crankshaft, that engine will work challenging, the crank plus cam go out of season, and this crankshaft may even break.

Billet Foremost Caps

With the manufacturing unit, solid foremost caps recognized to break down in excessive horsepower, excessive torque purposes (proper), a collection of Chromoly metal “billet” foremost caps was used to save the crankshaft.

Foremost Bearing Girdle

The declaring that “you’ll be able to’t overbuild a diesel” are useful phrases to dwell by, particularly within the diesel efficiency recreation. With a triple-digit increase, 3,000 psi value of cylinder strain, and tremendous torque on the faucet, it pays to add insurance coverage merchandise wherever you’ll be able to.

Billet Rocker Arms

A collection of D-pressure rocker streams can employ for lowered friction and attached power within the valvetrain. Noticeably more muscular than the inventory models, the variations create billet-aluminum, curler suggestions, billet spacers, including falling clamps.